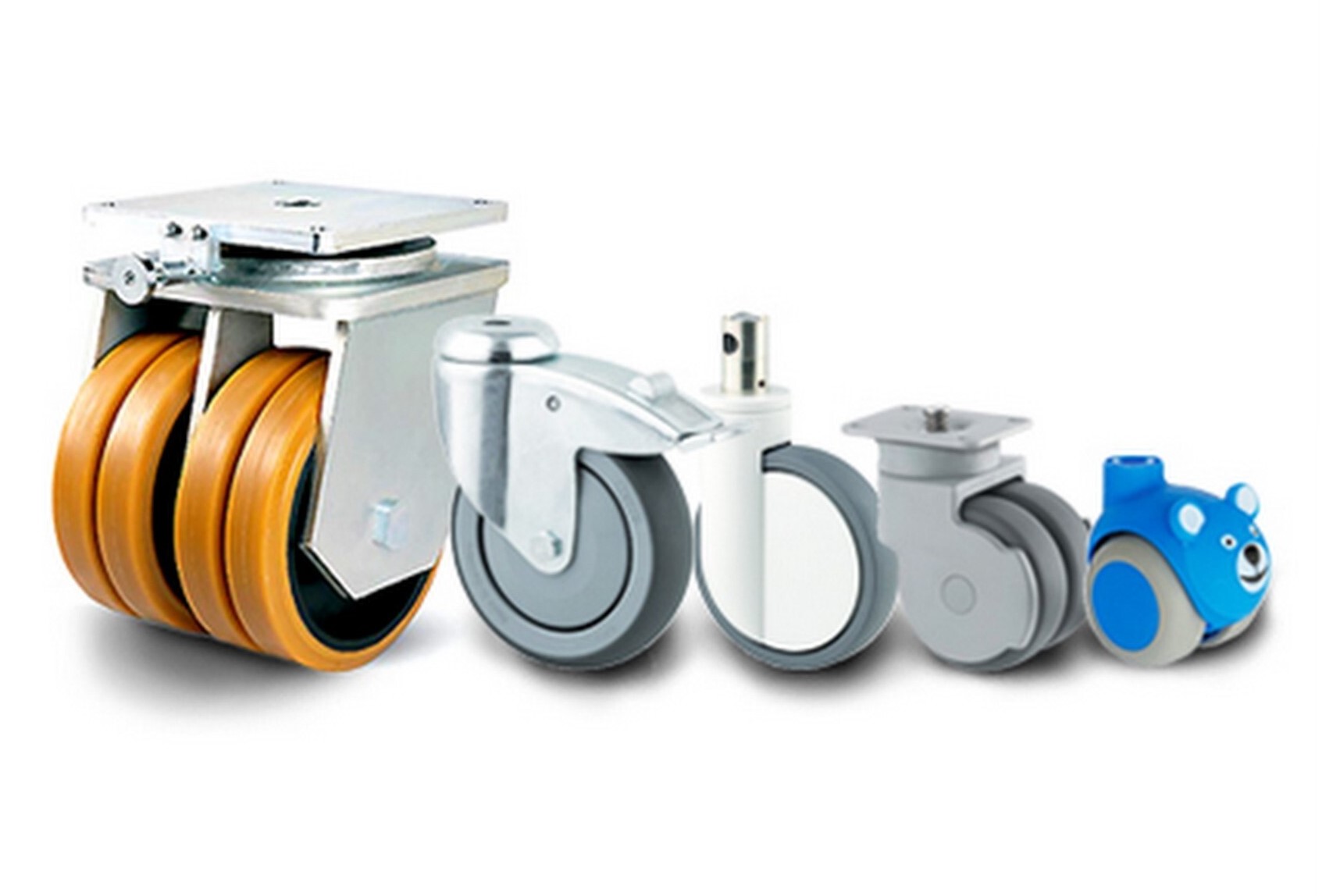

Castors can be utilised for a wide range of applications, ranging from office chairs to bookcases and dollies. But, just as important as obtaining the appropriate castor for the right application, is getting the correct size. Measuring key dimensions will guarantee that the castor will work properly for the purpose it’s intended.

Firstly it’s important to understand the type of castor wheel that you require for its intended purpose. Below we have named a few different things to consider, which will guide you in choosing the correct size castor.

Castor Wheel Considerations For Choosing Size

When deciding which kind of castor wheel you will need, you will need to calculate the total weight of the application as this will determine which castor size is fit for the job. Also, the environment in which the castor will be used is important in determining which castor is ideal, as different castors and sizes are better suited for different conditions.

Rollability

If your application is particularly large, tall, or heavy, it would be wise to choose a bigger castor wheel to remain safe and ensure that your application doesn’t fall over.

Also, choosing the appropriate bearing is critical to how well your castor rolls in use. A precision ball bearing is a smart investment for reducing the effort required to start and continue rolling.

Total Load

The maximum load a castor can support while in use is defined by the manufacturer, and going beyond that might cause damage and deterioration to the castor, which may lead to failure. As a result, it’s critical to know the maximum load you’ll need so that you can distribute it equally among the castors you intend on employing; more castors equals more load capacity for a cart or trolley.

Running Surface / Environment

In general, hard wheel materials should be used on soft flooring and soft wheel materials should be used on hard flooring to minimise damage to the wheels and scuffs on the floors. Choosing the proper type of wheel material from the start may save you a lot of hassle later. Knowing whether your castors will be used on surfaces like concrete or carpet will dictate which kind of castor you will need. As well as that, factors such as the temperature of the environment, and other external factors such as the slipperiness of the surface, should inform your decision on which castor should be used to remain safe. For example, a polyurethane castor is better suited for outdoor surfaces due to their strength and durability.

Deciding on the Correct Type of Castor

Now that we have established the different castor wheel considerations for choosing size, we now need to understand what is the correct type of castor for your requirements.

– Swivel – Swivel castors are ideal for situations that demand more mobility, such as when you’re working in a small area or in an environment where high amounts of agility is required. Swivel castors rotate 360 degrees and respond quickly to changes in direction.

– Total lock brakes – These are very simple to use; simply press your foot on the brake pedal to bring the application to a halt.

– Directional locking brake castors – A Directional locking brake castor may be used to secure the wheels in a 90 degree position, allowing one person to move a heavy piece of furniture or equipment through tight spaces.

Now that you have learnt about your castor requirements, and you have decided the type of castor that you need, it’s now time to discover how to properly measure them.

How To Measure For Replacement Castors

The size and dimensions of the castor wheel need to be properly measured, as well as the castor fitting plate. Here’s how to properly measure your replacement castor wheel:

Preparing to Measure for Replacement Castors

To accurately measure for replacement castors, you’ll need the right tools for the job. It’s quite a precise task, so make sure that you have the following tools handy to help:

- Ruler: Useful for measuring small dimensions accurately.

- Calliper: Ideal for precise measurements, especially the diameter of the wheel and the size of the mounting stem.

- Measuring Tape: Essential for measuring larger distances, such as the height from the ground to the mounting point, which can help determine the appropriate wheel diameter.

With these tools, you can ensure that you select the correct size castors for your equipment, enhancing performance and durability.

Measure the Top Plate and Bolt Hole Pattern

The top plate of a castor is used to attach the castor to a specific object. Because top plates come in different sizes, it’s important to measure the position where the castor will be attached and the top plate that will be used. On one side (length), measure from outside to outside of the top plate; then repeat this on the perpendicular side (width).

To calculate the bolt hole pattern size, measure in the same manner as previously, but this time measure from one hole to the next (length), and then repeat for width.

Wheel Size

Measuring the size of the wheel includes measuring the diameter and width. The diameter of the wheel is measured when it’s laid flat on its side with a measuring instrument. It’s critical to ensure that the measuring device passes over the center of the wheel during measurement. This guarantees that the measurement is accurate by ensuring that it’s centered. Stand up the wheel and measure from one side to the other for breadth measurements (width).

Swivel Radius

If swivel restrictions are a concern, knowing the swivel radius is essential. For example, when castors are attached to a cabinet, there is generally a skirt that runs along the bottom that conceals the wheels. If the swivel radius is too large and strikes the cabinet’s skirt, the castors will not be able to complete a full 360-degree rotation.

The swivel radius is the distance measured from the kingpin to the back of the wheel. The easiest way to measure this is when the castor is laid on its side and a straight edge is used against the wheel’s face. The straight edge should be long enough to make contact with your measuring equipment. The swivel radius measurement is calculated when the straight edge comes into touch with your measuring device.

Overall Height

When the overall height of the object you’re putting castors on is restricted, or if you’re replacing one castor out of a set of four, it’s vital to have an accurate idea of the overall height. If the replacement castor has a higher or lower overall height than the original castors, the surface with the castors attached will not be level. To determine how tall the castor is, you need to measure from the top plate to the bottom of the wheel, which can be done if the wheel is either on its side or standing up.

Once you have all of this information at your disposal, you can purchase your castors here at Tente, where there are many options to choose from, ensuring that you get the best fit for your application

Importance of the Correct Castor Size

Choosing the correct castor size is important for a few different reasons, ranging from performance to load distribution. By taking the time to choose the right size of castor, you’ll ensure that it will function optimally. Below we outline why you should always measure carefully to select the correct castor size:

Impact of Size on Performance

Choosing the right size for castor wheels directly affects their performance. The size of the wheel impacts how well it can manoeuvre and distribute the load. Larger wheels generally roll more easily over obstacles and uneven surfaces, which reduces the strain on the wheel and the overall structure of the cart or equipment. Conversely, smaller wheels are typically easier to control and manoeuvre in tight spaces, though they may not handle bumps and gaps as effectively.

How Size Affects Maneuverability and Load Distribution

The diameter and width of a castor wheel influence its manoeuvrability and how effectively it can distribute weight. A wider and larger diameter wheel will distribute the load over a larger area, reducing the pressure on any single point of the floor. On the other hand, smaller wheels concentrate the load more narrowly, which can increase the pressure on the wheel and the floor, potentially leading to damage over time.

Common Mistakes in Castor Selection

One common mistake in selecting castor sizes is underestimating the importance of wheel size for the specific application, leading to increased wear and tear or even failure of the castor system. Choosing a wheel that is too small can result in inadequate load distribution, increased rolling resistance, and quicker deterioration of the wheel material.

Another frequent error is ignoring the floor type, which can result in reduced mobility and increased damage both to the wheel and the floor surface. These mistakes can drastically shorten the lifespan of both the castors and the floors they’re used on, leading to higher maintenance costs and potential downtime for repairs.